- Woven Geotextiles

- Non-Woven Geotextiles

- High Strength Geocomposites

- HDPE Geomembrane

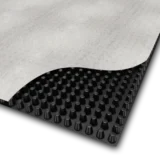

- Drainage Composites

- Geosynthetic Clay Liner (GCL)

- Geobags

- Geomattress

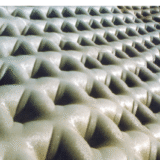

- Geocell

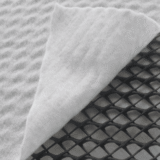

- Geo‑Net Drainage

- Geotextile Tubes

- Weed-Shield Geotextile

- Paving Fabric

- Silt Fence

- 3D Flex Grid

- Filterpoint Revetment

- Mining Grid

- Uniform Revetment

- Articulating Block Revetments (ABRs)

- Jute Geotextiles (JGT)

- Coir Geotextiles

- Gabion Box

- Geo-Pipe

- Geogrids

- Extruded Geogrids

Introduction

Woven geotextiles are synthetic fabrics manufactured by systematically interlacing yarns in a structured pattern. These engineered textiles provide reinforcement, separation, and filtration in geotechnical, civil engineering, and environmental projects. Unlike non-woven geotextiles, which have a random fiber arrangement, woven types offer superior strength and predictable performance due to their uniform weave.

Applications

- Road Construction: Reduces rutting by separating subgrade from aggregate.

- Railway Tracks: Stabilizes ballast layers.

- Erosion Control: Protects slopes and retaining walls.

- Coastal Protection: Prevents soil washout in revetments.

- Landfills: Act as a separator in waste containment systems.

- Mining: Reinforces haul roads and tailings dams.

Introduction

Non-woven geotextiles are specially engineered fabrics made from synthetic polymer fibres such as polypropylene or polyester. Unlike woven fabrics, these are created by bonding fibres through mechanical needling, heat treatment, or chemical binding. They serve vital roles in civil, environmental, and geotechnical works by performing separation, filtration, drainage, and protection functions. Owing to their high strength, permeability, and resistance to environmental wear, they are widely adopted in roads, erosion control, landfills, and water management projects.

Applications

- Transport Infrastructure: Roads and railway beds for subgrade separation and load spread.

- Landfill Engineering: Cushioning and protecting geomembranes while managing leachate flow.

- Erosion Protection: Under riprap or gabions to stop soil loss at coasts and rivers.

- Sports & Landscape Projects: Enhances drainage and soil stability.

- Underground Works: Provides drainage and protection in tunnels.

Introduction

Definition

High-strength geocomposites are advanced geosynthetic materials formed by combining two or more components—such as geotextiles, geogrids, geomembranes, or drainage cores—into a layered system. This integration enhances their mechanical, hydraulic, and protective performance, making them suitable for demanding civil, geotechnical, hydraulic, and environmental projects.

Main Components

- Geotextiles: Permeable fabrics that provide separation, filtration, and reinforcement.

- Geogrids: Grid-structured materials that supply high tensile strength for soil and aggregate reinforcement.

- Geomembranes: Impermeable polymeric sheets used mainly for containment of liquids or gases.

- Drainage Cores: Structured elements that facilitate water flow and relieve hydrostatic pressure within soil systems.

Applications

- Reinforced Soil Systems: Used in retaining walls, steep slopes, and embankments for stability.

- Transportation Infrastructure: Improves subgrade conditions and base layers in road construction.

- Waste Containment: Functions as both a liner and a drainage layer in landfills.

- Railway Engineering: Enhances load distribution and reduces track settlement.

- Hydraulic Works: Controls seepage and aids drainage in reservoirs, canals, and other water management systems.

Definition

An HDPE (High-Density Polyethylene) Geomembrane is a tough, impermeable lining sheet produced from polyethylene resin. It is widely used in civil, environmental, and industrial engineering to prevent fluid migration and ensure effective containment in diverse applications.

Applications

- Landfills:

- Acts as a base liner to prevent leachate from entering the ground.

- Serves as a final cover to isolate waste from the environment.

- Mining Industry:

- Lines heap leach pads, tailings dams, and process ponds.

- Tolerates strong chemicals used in mineral extraction.

- Water Retention Systems:

- Lines reservoirs, canals, ponds, and dams to prevent water loss.

- Wastewater Facilities:

- Applied in sewage lagoons and digesters for containment and treatment.

- Agriculture:

- Used in silage storage, biogas digesters, and irrigation ponds.

Definition

Drainage composites are engineered systems made from a combination of geosynthetic materials that facilitate effective water movement and pressure relief in soil and structural systems. They are widely used in civil, geotechnical, and environmental engineering projects where proper drainage is essential to maintaining stability and preventing structural damage.

Applications

- Retaining Walls: Placed behind walls to drain groundwater and relieve pressure.

- Landfills and Waste Containment: Integrated into liner systems to manage leachate and gases.

- Tunnel and Basement Waterproofing: Prevents water intrusion by channeling it away from structural surfaces.

- Green Roof Systems: Facilitates drainage while protecting waterproof membranes.

- Roads and Highways: Used beneath pavements or embankments to control subsurface water.

- Sports Fields and Golf Courses: Ensures quick drainage and usability after rain.

- Environmental Efficiency: Manufactured from recyclable polymers; often considered more sustainable.

Definition

A geosynthetic clay liner (GCL) is a factory-produced barrier designed for hydraulic containment. It consists of a thin layer of sodium bentonite clay positioned between two layers of geotextile fabric, sometimes paired with geomembrane layers for added impermeability.

Applications

GCLs are used in diverse settings, such as:

- Landfills: Serve as liners and capping layers to block leachate migration.

- Water Storage & Control: Provide seepage barriers in reservoirs, canals, ponds, and dams.

- Mining Sites: Line tailings ponds and heap leach pads to contain hazardous substances.

- Industrial Waste Facilities: Function as liners for storing toxic or hazardous materials.

- Infrastructure Projects: Used beneath roads, railways, and embankments to stabilize and prevent water ingress.

- Eco-Restoration: Protects wetlands and groundwater by acting as a hydraulic barrier.

Definition

Geobags—also known as geo-bags or geotextile bags—are sturdy containers constructed from synthetic textiles such as polypropylene or polyester, either woven or non-woven. These bags are filled with locally available materials like sand, soil, or gravel at the project site, forming permeable, flexible blocks that serve various geotechnical and environmental roles.

Applications

- Coastal & Riverbank Protection: Geobags act as barriers to absorb wave energy and minimize shoreline erosion.

- Slope Stabilization & Erosion Control: Used to reinforce embankments, reducing the risk of landslides.

- Flood Defense: Arranged swiftly to form sand-filled walls for flood mitigation and temporary barriers.

- Dewatering & Sediment Control: Specialized types, including dewatering tubes, help filter out water from sediments, useful for construction sites, mining, and wastewater systems.

- Infrastructure Support: Deployed in ports, harbors, groynes, breakwaters, land reclamation, and shoreline strengthening.

- Illustrative Case: In Chellanam, Kerala, a stretch of 961 meters was protected using geobag installations as a temporary coastal shield, though calls for permanent solutions remain.

Definition

A geomattress is a flexible, three-dimensional formwork made from geotextile fabrics such as high-strength polypropylene or polyester. These porous pockets or envelopes are filled on-site with materials like concrete, sand, or mortar. The resulting structure forms a stable, conformable layer used for erosion protection and slope reinforcement.

Typical Applications

- Reinforcement of riverbanks, canal slopes, and embankments.

- Shoreline protection and coastal defense.

- Revetments for dikes and sea walls.

- Underwater safeguarding of pipelines and submarine infrastructure.

- Land reclamation areas and erosion-prone slopes.

- Landscaping for ponds, irrigation channels, and water bodies.

Definition & Form

A geocell, also called a cellular confinement system, is a three-dimensional, honeycomb-like structure made from interconnected polymer strips, usually high-density polyethylene (HDPE) or similar durable materials. These strips are joined by methods such as ultrasonic welding. The panels are expanded accordion-style over the subgrade to form a grid of cells, which are then filled with materials like soil, sand, gravel, or recycled aggregates to provide ground reinforcement.

Applications

- Roads & Railways: Reinforcement of subgrades and base layers to enhance pavement durability and reduce aggregate consumption.

- Slope and Channel Stabilization: Secures slopes up to 70 degrees and prevents erosion using rock or vegetation infill.

- Retaining Structures: Used in gravity and mechanically stabilized earth walls where geocell layers reinforce fill material and allow vegetated facings.

- Channel & Shoreline Protection: Controls erosion and stabilizes embankments in hydraulic settings.

- General Ground Improvement: Facilitates the use of low-quality, marginal, or recycled materials for cost-effective and eco-friendly construction.

Definition

A Geo‑Net (or Geonet) is a geosynthetic drainage core constructed from high‑density polyethylene (HDPE). It has a three‑dimensional mesh geometry—most commonly in bi‑planar or tri‑planar patterns—that allows liquids or gases to flow laterally under soil, geomembranes, or other coverings.

- Bi‑planar design: Two intersecting rib layers, typically set at about 60°, forming a durable and open drainage path.

- Tri‑planar design: Adds a central rib layer between two angled rib sets, improving compressive strength and maintaining high flow rates under load.

Applications

- Landfills: Collect leachate and vent gases between lining layers.

- Retaining Walls & Basement Walls: Relieve hydrostatic pressure behind structures.

- Roads, Railways & Pavements: Keeps subgrades dry, reducing structural deterioration.

- Tunnels & Foundations: Minimizes seepage and protects against structural damage.

- Green Roofs & Landscaping: Provides lightweight sub‑soil drainage.

- Environmental Protection Works: Reduces frost heave risk and limits salt migration in cold climates.

Definition

Geotextile tubes, also called geotubes, are large tubular containers made from durable, permeable geotextile fabrics such as woven polypropylene or polyester. These tubes are hydraulically filled with materials like sand, sludge, or dredged sediments. Their permeable walls allow water to filter out while retaining solid particles inside, forming continuous, flexible structures for various engineering uses.

Applications

- Coastal and Shore Protection: Used as breakwaters, revetments, artificial dunes, and quays to prevent erosion and protect shorelines from wave action.

- Dewatering and Sludge Containment: Employed in dredging, wastewater treatment, and sediment management to consolidate solids and release clear water.

- Erosion Control and Land Reclamation: Suitable for stabilizing embankments, constructing temporary dams or islands, reclaiming land, and supporting environmental clean-up efforts.

- Environmental and Ecological Restoration: Aid in wetland restoration, habitat enhancement, and sediment containment in sensitive ecological zones.

Definition

Weed-shield geotextile, also known as landscape fabric or weed barrier, is typically made from non-woven polypropylene or polyester fibers. It serves as a durable, permeable layer that suppresses weed growth by blocking sunlight while allowing water, air, and nutrients to reach the soil beneath.

Applications

- Weed Control: Acts as a physical barrier that limits sunlight, effectively curbing weed growth.

- Moisture Retention: Helps conserve soil moisture by reducing evaporation, beneficial in dry environments.

- Erosion and Temperature Regulation: Protects soil from erosion and moderates soil temperature fluctuations.

- Environmental and Maintenance Benefits: Decreases reliance on herbicides, requires minimal maintenance post-installation, and promotes healthier plant growth.

- Durability and Versatility: UV-resistant and tear-resistant fabrics come in various weights and can be tailored for applications like gardens, pathways, or hardscapes.

Definition

Paving fabric is a type of non-woven geotextile, commonly made from polypropylene, placed between an existing pavement and a new asphalt overlay. It acts as a stress-absorbing membrane that improves the new overlay’s durability and structural performance.

Application

- Crack Mitigation: Serves as a barrier to reflective cracking, preventing cracks from the underlying pavement from resurfacing through the overlay.

- Moisture and Water Shield: Reduces infiltration of water into the base layers, thereby protecting the pavement’s structural integrity.

- Structural Support: Enhances flexibility and helps distribute loads within the pavement system, improving overall performance.

- Extended Pavement Lifespan: Helps delay deterioration and reduces the need for frequent repairs.

- Reduced Maintenance Costs: Protects against water damage and cracking, cutting down repair frequency and expenses.

- Stress Relief: Functions as a flexible interlayer that absorbs shear and thermal stresses, improving overlay resilience.

Definition

A silt fence is a temporary sediment control barrier made from woven or non-woven geotextile fabric, installed at construction sites or disturbed land to allow water passage while capturing sediments. Its primary function is to prevent soil particles from entering nearby water bodies.

Application

- Sediment Interception: It slows down sheet flow across the site, causing heavier soil particles to settle out before water moves beyond the fence.

- Pollution Prevention: The fence helps protect streams, lakes, and drains from sediment pollution generated onsite.

Definition

The 3D Flex Grid is a three-dimensional geogrid made from polymer materials, characterized by a raised, textured grid structure instead of a flat surface. This multi-layered design enhances lateral soil confinement and strengthens the interlock between soil and the grid. For instance, the Tenax 3D GRID series offers MS, S, and XL models tailored for various soil types and load requirements.

Applications

- Roads and Railways: Reinforces base layers, reducing rutting and allowing for shallower pavement constructions.

- Pavement Reinforcement: Improves load distribution and limits deformation under heavy traffic conditions.

- Soft Subgrades and Weak Soils: Facilitates the use of local, lower-quality materials, decreasing the need for imported aggregates and improving foundation stability.

Definition

Filterpoint Revetment is a specialized geosynthetic erosion control system designed to provide durable and permeable concrete linings for hydraulic structures. It consists of a double-layer woven fabric with woven-in filter points that connect the layers. These filter points allow water to pass through, relieving hydrostatic uplift pressures and enhancing the stability of the revetment. The system is usually filled on site with flowable concrete or mortar, forming a robust, cobbled surface suitable for areas experiencing low hydraulic loads.

Applications

Filterpoint Revetment is widely used in hydraulic engineering for:

- Ditches and Channels: Controls erosion in agricultural and drainage systems.

- Canals and Streams: Protects banks from erosion caused by water flow.

- Reservoirs and Ponds: Stabilize embankments and prevent soil erosion.

- Marinas and Harbors: Shields against wave action and sediment displacement.

- Bridge Abutments and Shorelines: Enhance stability and protect from erosion.

Definition

A Mining Grid is a specialized geosynthetic reinforcement product designed to improve the structural strength and safety of mining sites. Constructed primarily from high-strength polymers such as polyester or polypropylene, these grids endure the demanding conditions typical in mining environments, including exposure to harsh chemicals, heavy loads, and temperature fluctuations. They are extensively utilized in underground mining for supporting roofs and ribs, stabilizing slopes, reinforcing haul roads, and controlling erosion.

Applications

- Roof and Rib Control: Stabilizes mine ceilings and walls, minimizing collapse risks and ensuring worker safety.

- Slope Stabilization: Used in open-pit mines to secure slopes, preventing landslides and protecting personnel.

- Haul Road Reinforcement: Embedded in haul roads to uniformly distribute load, reduce rut formation, and prolong road life.

- Erosion Control: Helps prevent soil erosion around mining sites, preserving environmental integrity and site stability.

Definition

A uniform revetment is an erosion control structure featuring a consistent, even protective layer, typically built from concrete, stone, or geosynthetic materials. Its main role is to safeguard shorelines, riverbanks, and other at-risk zones from the erosive impact of waves, currents, and storm surges.

Applications

Uniform revetments are used in many civil and environmental engineering projects, such as:

- Coastal Protection: Defending beaches, coasts, and waterfronts against wave action and storm-induced erosion.

- Riverbank Stabilization: Retaining soil and preventing riverbank collapse.

- Infrastructure Protection: Shielding transport routes and structures located near water bodies.

- Flood Management: Strengthening flood defences to withstand elevated water levels.

Introduction

Articulating Block Revetments (ABRs) are engineered erosion control solutions designed to shield soil surfaces from the damaging effects of water flow. They consist of interlocking concrete blocks connected either by cables or geogrids, forming a flexible yet durable protective layer. ABRs are especially effective in environments exposed to high-velocity water flows, wave action, or varying water levels.

Applications

ABRs are versatile and suited for various uses, including:

- Coastal Protection: Guarding shorelines against erosion caused by waves.

- River and Stream Bank Stabilization: Preventing erosion from currents.

- Spillways and Culverts: Protecting these structures from damage by fast-moving water.

- Bridge Abutments and Embankments: Preventing soil loss and undermining effects.

- Landfill Caps and Channel Erosion Control: Used in environmental projects to control soil erosion.

Introduction

Jute geotextiles are natural, biodegradable fabrics made from the jute plant species, primarily Corchorus capsularis and Corchorus olitorius. Available as woven or nonwoven materials, these eco-friendly textiles are widely applied in civil engineering, agriculture, and environmental fields, providing a sustainable substitute for synthetic geotextiles.

Applications

Civil Engineering:

- Prevent soil erosion on slopes, embankments, and riverbanks by reducing runoff and fostering vegetation.

- Stabilize slopes by acting as mini check dams dissipating kinetic energy from rain and wind.

- Reinforce foundations to evenly distribute loads and reduce cracking risks.

- Serve in drainage systems to filter water while blocking soil and debris.

- Enhance road subgrade stabilization and prevent pavement cracking.

Agriculture and Horticulture:

- Natural weed barriers, reducing dependence on chemical herbicides.

- Promote sapling growth by providing aeration and regulating temperature, especially in high-altitude areas.

- Aid in conserving soil moisture and nutrients, boosting plant development.

Environmental Applications:

- Facilitate afforestation in dry regions by supporting plant growth and moisture retention.

- Assist in rehabilitating mine spoils by preventing erosion and encouraging vegetation establishment.

Introduction

Coir geotextiles are natural, biodegradable fabrics produced from coconut husk fibers. Widely used in civil engineering, agriculture, and environmental projects, these geotextiles are valued for their eco-friendly qualities and effectiveness in erosion control and soil stabilization. Their increasing use marks a shift toward sustainable alternatives to synthetic geotextiles.

Applications

- Erosion Control: Commonly applied on slopes, riverbanks, and coastal areas, coir geotextiles stabilize soil, reduce runoff, and support vegetation that strengthens the ground.

- Road and Railway Construction: Used as a separation layer between soil and aggregates, they improve load distribution and prevent material mixing while also assisting drainage to protect infrastructure.

- Land Reclamation and Slope Stabilization: Coir supports seed germination, retains soil moisture, and avoids erosion, aiding vegetation establishment on reclaimed land.

- Agriculture and Horticulture: They help retain soil moisture, suppress weeds, regulate soil temperature, and promote healthy root development and even water distribution.

- Ecological Restoration: Utilized in reforestation and wetland restoration to foster biodiversity and strengthen ecological resilience.

Introduction

Gabion boxes are sturdy wire mesh cages filled with stones, rocks, or similar durable materials. They are extensively used in civil engineering, landscaping, and environmental protection works due to their strength, adaptability, and natural drainage capability. Common uses include erosion prevention, retaining structures, slope stabilization, and safeguarding riverbanks against scouring.

Applications

- Retaining Walls: Supporting slopes, terraces, and embankments.

- Erosion Control: Protecting riverbanks, coastal zones, and shorelines by dissipating wave and current energy.

- Slope Stabilization: Reinforcing weak slopes to prevent landslides.

- Flood Management: Guiding and slowing floodwaters in drainage or irrigation systems.

- Road Construction: Serving as retaining structures and stabilizing road embankments.

- Landscaping: Creating visually appealing garden walls and other decorative features.

Introduction

A Geo Pipe is a specialized drainage pipe engineered for efficient water management in civil engineering projects. It consists of a perforated or slotted pipe wrapped with a geotextile filter fabric. This combination effectively filters water while preventing soil intrusion, ensuring reliable drainage. Geo pipes are widely used in subsoil drainage, behind retaining walls, landfills, and other applications requiring controlled water flow.

Applications

- Subsoil Drainage: Installed underground to remove excess water from soils, preventing waterlogging and supporting healthy vegetation.

- Behind Retaining Walls: Helps manage hydrostatic pressure to protect retaining walls from water-related damage or failure.

- Landfills: Used for leachate collection and management to protect environmental quality.

- Agricultural Drainage: Enhances soil aeration and prevents crop root diseases by mitigating excess moisture.

- Road and Railway Construction: Incorporated into embankments to control water flow and safeguard structural integrity.

Definition

Geogrids are two-dimensional geosynthetic materials designed to reinforce and stabilize soils and aggregates in engineering applications. They consist of a network of intersecting ribs forming apertures, which allow soil particles to interlock with the grid, thus enhancing the soil’s load-bearing capacity and overall stability.

Composition and Structure

Geogrids are made from high-tensile polymers selected for their strength and durability, including:

- Polyester (PET): Known for high tensile strength and creep resistance, suitable for applications needing long-term reinforcement.

- Polypropylene (PP): Lightweight and chemically resistant, ideal for soil reinforcement and retaining wall systems.

- Polyethylene (PE): Durable against harsh environmental conditions, effective in chemically aggressive soils.

Applications

Geogrids serve multiple roles in infrastructure projects:

- Pavement and Road Construction: Enhance base layer strength, reducing rutting and cracking from heavy traffic.

- Retaining Walls and Slopes: Improve stability against vertical and lateral loads, enabling steep slope reinforcement.

- Rail Trackbeds: Increase stiffness, reduce settlement, and mitigate ballast degradation.

- Embankments and Foundations: Strengthen weak subgrades to support embankments and structural loads.

- Landfill Liners: Reinforce containment systems to maintain integrity and prevent waste escape.

Definition

Extruded geogrids are specialized geosynthetic materials engineered to reinforce and stabilize soil in civil engineering projects. Created through an extrusion process, these geogrids offer high tensile strength, durability, and excellent interlocking with soil, which enhances load distribution and prevents deformation.

Types of Extruded Geogrids

- Uniaxial Geogrids: Stretched in one direction to provide high tensile strength along that axis. Commonly utilized for slope stabilization and retaining wall reinforcement.

- Biaxial Geogrids: Stretched in two perpendicular directions, offering balanced tensile strength suitable for reinforcing road bases, foundations, and other structural elements.

Applications

Extruded geogrids find use across many civil engineering domains, including:

- Railway Trackbed Stabilization: Improving track stability and prolonging service life.

- Embankment Reinforcement: Supporting embankments, particularly on weak soils.

- Retaining Walls: Enhancing the strength and durability of retaining structures.

- Reinforced Soil Slopes: Preventing erosion and soil slippage.

- Bridge and Railway Abutments: Providing foundational support.

- Reinforced Foundations Over Piles: Distributing loads effectively in pile-supported foundations.

- Load Transfer Platforms: Improving load distribution where subgrade strength is insufficient.